Product Overview

The L295 Dual-Switch Mode Solenoid Driver IC is a high-efficiency dual-channel driver designed for controlling solenoids, relays, motors, and inductive loads. It features switch-mode operation, which significantly reduces power dissipation while ensuring high-performance control. With adjustable current regulation, thermal protection, and wide voltage operation, the L295 is ideal for industrial automation, automotive systems, and robotics applications.

Key Features:

- Dual-Channel Driver – Controls two solenoids, relays, or motors independently.

- Switch-Mode Operation – Reduces power loss and improves efficiency.

- Adjustable Current Regulation – Enables precise control over the output current.

- Wide Operating Voltage Range – Supports 6V to 36V power supply.

- Overtemperature Protection – Prevents damage due to overheating.

- Overcurrent Limiting – Ensures safe operation with inductive loads.

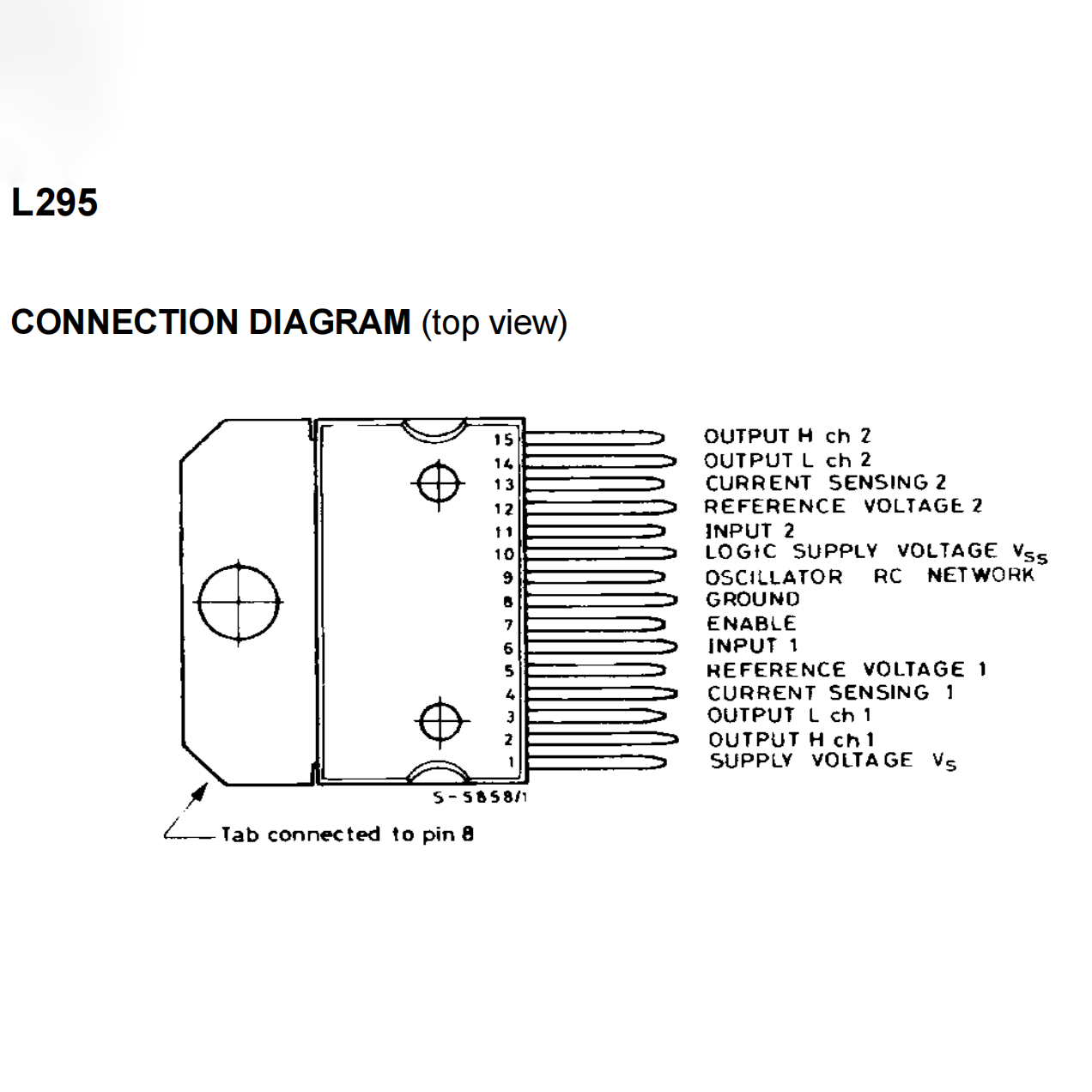

- Compact Package – Available in a multi-pin PowerDIP package for easy integration.

Technical Specifications:

- Model: L295

- Number of Channels: 2

- Operating Voltage: 6V – 36V

- Maximum Output Current: 2A per channel

- Switching Frequency: Adjustable up to 20kHz

- Current Regulation: Adjustable via external resistors

- Protection Features: Thermal shutdown, overcurrent protection

- Power Dissipation: Reduced due to switch-mode operation

- Package Type: PowerDIP-15

Applications:

- Solenoid & Relay Control – Ideal for industrial automation and control systems.

- Automotive Systems – Used in fuel injectors, actuators, and other vehicle applications.

- Motor Drive Circuits – Provides efficient control for small DC motors.

- Robotics & Mechatronics – Ensures precise actuation of mechanical components.

- Industrial Equipment – Powers solenoids and electromagnetic devices with minimal heat dissipation.

Why Choose the L295?

With dual-channel control, efficient switch-mode operation, and built-in protection features, the L295 Solenoid Driver IC is an ideal choice for engineers looking for a versatile and power-efficient solution for controlling inductive loads.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.