Product Overview

The Servo Motor NISCA NF5475 with 200ppr Encoder is a high-precision, brushless servo motor designed for industrial automation, robotics, and CNC applications. Featuring a robust closed-loop control system and a high-resolution encoder, this motor delivers exceptional accuracy, torque stability, and dynamic response. Its rugged construction and advanced thermal management ensure reliable performance in demanding environments.

Key Features

- High-Resolution Encoder: 200 pulses per revolution (ppr) for precise position/speed feedback.

- High Torque Density: Continuous torque up to 4.5 Nm for heavy-duty applications.

- Wide Speed Range: 0–3,000 RPM with smooth velocity control.

- Closed-Loop Control: Compatible with industrial servo drives for real-time adjustments.

- Durable Design: IP65-rated housing protects against dust and moisture.

- Low Cogging: Precision-machined rotor for minimal torque ripple.

- Compliance: CE, RoHS, and REACH certified.

Technical Specifications

- Motor Type: Brushless AC Servo

- Rated Power: 750W

- Voltage Rating: 220V AC (3-phase)

- Continuous Torque: 4.5 Nm

- Peak Torque: 13.5 Nm

- Encoder Type: Incremental (200ppr) with index pulse

- Feedback Interface: Differential line driver (A+/A-, B+/B-, Z+/Z-)

- Rotor Inertia: 0.0025 kg·m²

- Operating Temperature: -20°C to +80°C

- Weight: 3.2 kg

- Shaft Diameter: 14mm (keyed shaft with dual seals)

Benefits

- Precision Positioning: Ideal for CNC machines and robotic arms requiring micron-level accuracy.

- Energy Efficiency: >90% efficiency reduces operational costs.

- Easy Integration: Standard mounting dimensions (NEMA 23) and connectors.

- Long Lifespan: High-quality bearings and minimal wear due to brushless design.

- Noise Reduction: Smooth operation in sensitive environments like medical devices.

Usage Instructions

- Mounting: Secure the motor using M4 bolts; align shaft couplings precisely.

- Wiring: Connect encoder feedback and power cables to a compatible servo drive.

- Configuration: Tune PID parameters via drive software for optimal performance.

- Calibration: Use the encoder index pulse for homing/zero-position alignment.

- Testing: Gradually increase load to verify torque and speed stability.

Safety & Storage

- Handling: Avoid mechanical shock or misalignment during installation.

- Storage: Keep in a dry, vibration-free environment (-20°C to +50°C).

- Operational Limits: Do not exceed peak torque or max RPM to prevent overheating.

- Maintenance: Periodically check bearings and seals; replace if worn.

Applications

- CNC milling machines and lathes

- Industrial robotic arms (pick-and-place, welding)

- Automated packaging and assembly lines

- Semiconductor manufacturing equipment

- Medical imaging devices and precision actuators

- AGV (Automated Guided Vehicle) propulsion systems

Why Choose the NISCA NF5475?

This servo motor combines cutting-edge encoder technology, industrial-grade durability, and unmatched precision for mission-critical automation tasks. Its 200ppr encoder ensures sub-degree positioning accuracy, while the IP65 rating and high torque density make it adaptable to harsh, high-load environments. Whether optimizing CNC workflows or advancing robotic agility, the NF5475 delivers performance that meets the strictest industrial standards.

Example Code to Control the NISCA NF5475 with an Encoder

To control the NISCA NF5475 servo motor utilizing its encoder for position control, you typically use a microcontroller such as an Arduino. Below is an example code demonstrating how to read the encoder’s position and control the motor based on that data.

Required Components:

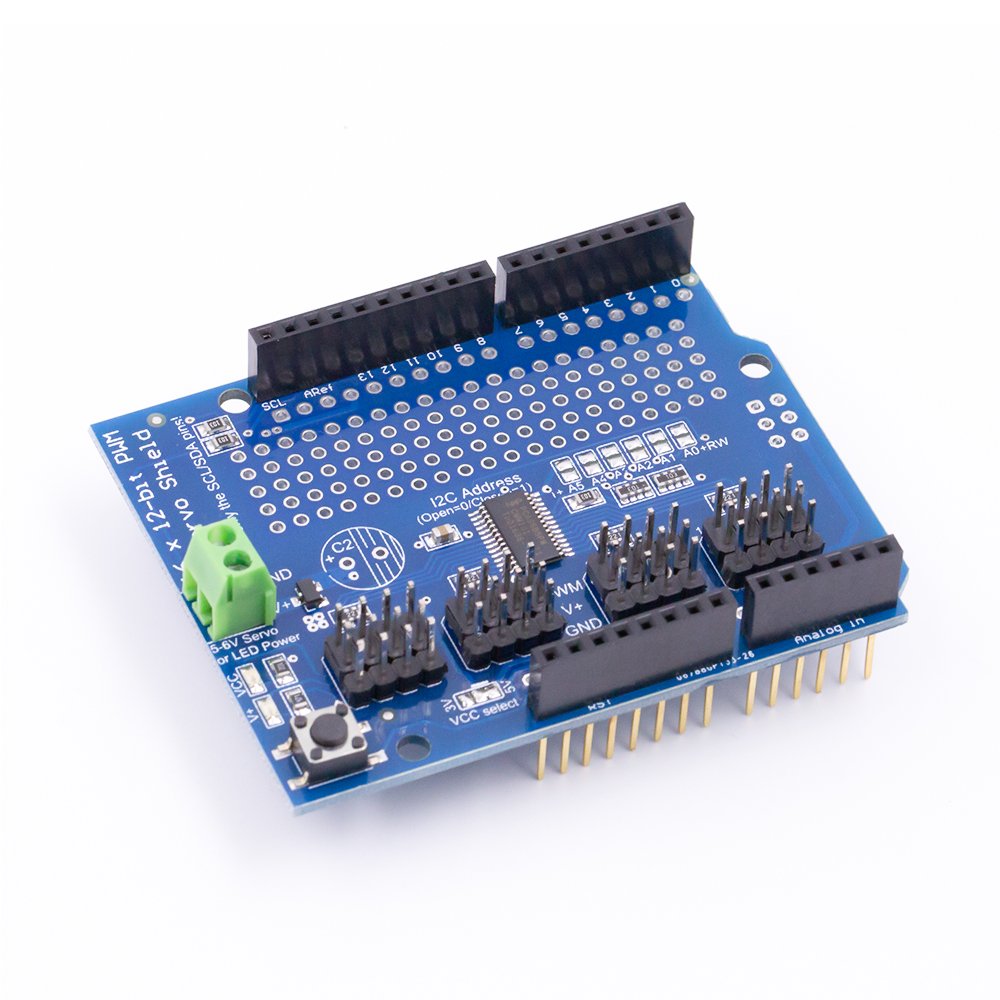

- 1 x Arduino board (e.g., Arduino Uno)

- 1 x NISCA NF5475 Servo Motor with Encoder

- 1 x Motor Driver (suitable for your servo motor, e.g., Sabertooth or similar)

- Jumper wires for connections

- External power supply (according to the motor specifications)

Arduino Code

#include <Encoder.h> // Include the Encoder library

// Define pins for the motor driver

const int motorPWM = 9; // PWM pin for controlling motor speed

const int motorDIR = 8; // Direction pin for motor

// Define encoder pins

const int encoderA = 2; // Encoder A pin

const int encoderB = 3; // Encoder B pin

// Create encoder object

Encoder encoder(encoderA, encoderB);

// Target position in encoder counts

long targetPosition = 800; // Example target position (adjust as needed)

void setup() {

// Initialize motor driver pins

pinMode(motorPWM, OUTPUT);

pinMode(motorDIR, OUTPUT);

// Initialize serial communication for debugging

Serial.begin(9600);

}

void loop() {

long currentPosition = encoder.read(); // Read current encoder position

// Output current position to the serial monitor

Serial.print("Current Position: ");

Serial.println(currentPosition);

// Control motor direction based on target position

if (currentPosition < targetPosition) {

digitalWrite(motorDIR, HIGH); // Set motor direction

analogWrite(motorPWM, 255); // Full speed

}

else if (currentPosition > targetPosition) {

digitalWrite(motorDIR, LOW); // Reverse direction

analogWrite(motorPWM, 255); // Full speed

}

else {

analogWrite(motorPWM, 0); // Stop the motor when at target

}

// Small delay for stability

delay(100);

}Explanation of the Code:

- Libraries: The code uses the

Encoderlibrary for reading the position from the encoder. Make sure to install theEncoderlibrary in the Arduino IDE. - Motor Control Pins: PWM and direction pins are defined to control the motor driver.

- Encoder Pins: Pins for the encoder are set up to read its state.

- Target Position: A target position in encoder counts is defined, which can be adjusted as per your application.

- Loop Logic: The loop continuously reads the current position from the encoder and compares it to the target. The motor runs in the appropriate direction at full speed until the target is reached, at which point it stops.

Conclusion

This code provides a basic framework for controlling a NISCA NF5475 servo motor with a 200 PPR encoder. The code can be extended for more complex control algorithms, such as PID control, depending on project requirements. Always refer to the motor’s specific datasheet and driver specifications for any adjustments needed for your design to ensure optimal performance and reliability.

| Number of degrees |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.